ORP Module with Electrode Water Quality Detection Analog Output for Arduino/51/STM32

Description:

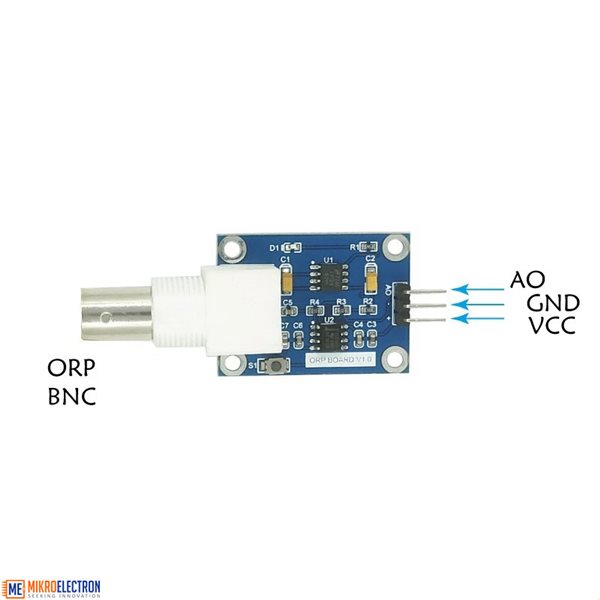

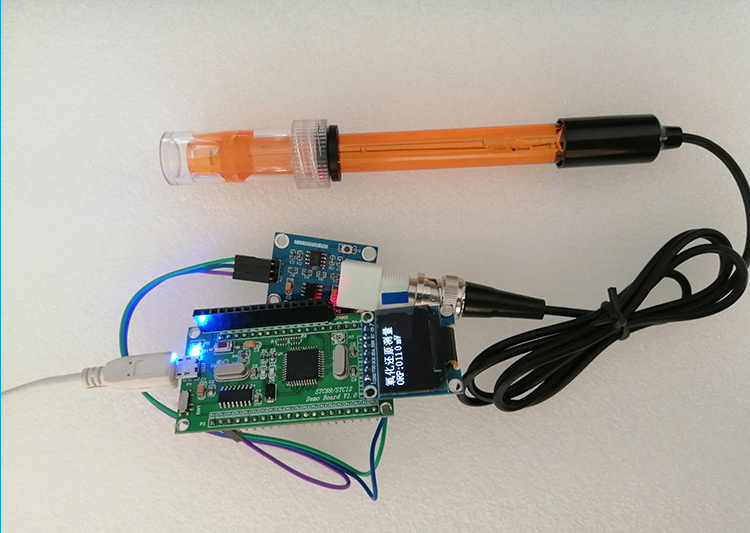

Step 4: Connect the ORP electrode to the BNC interface of the ORP sensor module. After rewriting the revised program, the ORP value of the solution can be measured.

Note:

Matters needing attention:

1. The power supply voltage of the ORP module should be as close as possible to +5.00V. The more accurate the voltage, the higher the accuracy!

2. The ORP electrode can be used directly without calibration. Only when there is doubt about the quality of ORP electrode or test result, the electrode potential can be checked with ORP standard solution to judge the quality of ORP electrode or instrument.

3. Every solution tested with ORP electrode needs to be cleaned with clean water. It is recommended to clean with deionized water.

4. When the ORP electrode is connected to the ORP meter circuit board, it is strictly prohibited to press the calibration button, otherwise the ORP electrode will be damaged!

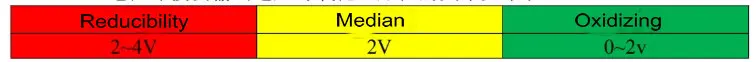

5. As the temperature increases, the ORP value of the solution decreases significantly and has a good linear relationship. Therefore, when describing the ORP value of the solution, the current solution temperature must be marked to have practical significance.

ORP electrode maintenance and precautions:

1. The ORP composite electrode does not need to be calibrated when used, and can be directly connected to the instrument for use. Only when there is doubt about the electrode test results, you can use a standard solution to test its mV value as a method to judge the quality of the electrode

2. There is an appropriate amount of electrode immersion liquid in the protective bottle at the front of the electrode. The electrode head is immersed in it. Before measuring, unscrew the bottle cap, pull out the electrode, wash it with pure water and spin it dry before using it. ), the electrode should be agitated in the solution and placed at rest during the measurement to speed up the response. After the measurement, the electrode should be rinsed with pure water, inserted into the protective bottle and screwed on the cap to prevent the leakage of the soaking solution, if the protective bottle is found The immersion liquid in the turbidity and moldy phenomenon should be washed in time and replaced with a new immersion liquid.

3. Configuration of electrode soaking solution: Take a pack of PH4.0 buffer, dissolve it in 250ml of pure water, add 56g of analytically pure potassium chloride, heat properly with an electric furnace, stir until completely dissolved and serve.

4. ORP electrode cleaning and activation: After long-term use of the ORP electrode, the contamination of sensitive components will lead to inaccurate measurement and slow response. At this time, the following methods can be used for cleaning and activation;

A. For contamination of inorganic substances, the electrode can be put into 0.1mol/L dilute hydrochloric acid for 30min, washed with pure water, and then immersed in the soaking solution for 6 hours before use.

B. For organic oil and oil film pollution, the sensitive components can be cleaned with detergent and then washed with pure water, and then immersed in the electrode soaking solution for 6 hours before use.

C. Sensitive components are heavily contaminated to form an oxide film or a reduced film. You can use finer metallographic sandpaper to polish the surface of the sensitive component, then clean it with pure water, then immerse it in pure water, and then immerse it in the electrode immersion solution for 6 hours After use.

Kit include:

1 x ORB Module

1 x ORB Electrode

Related Products

subscribe to our weekly newsletter