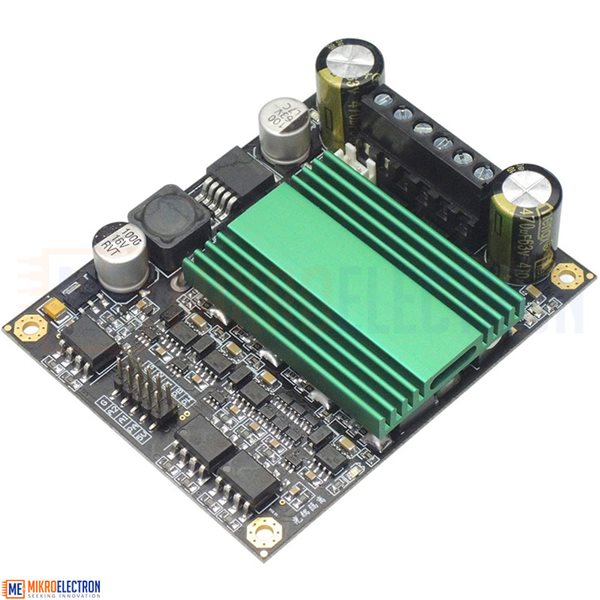

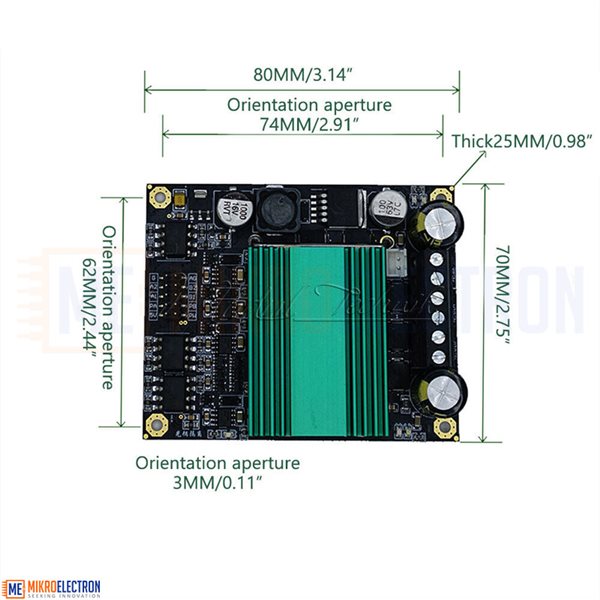

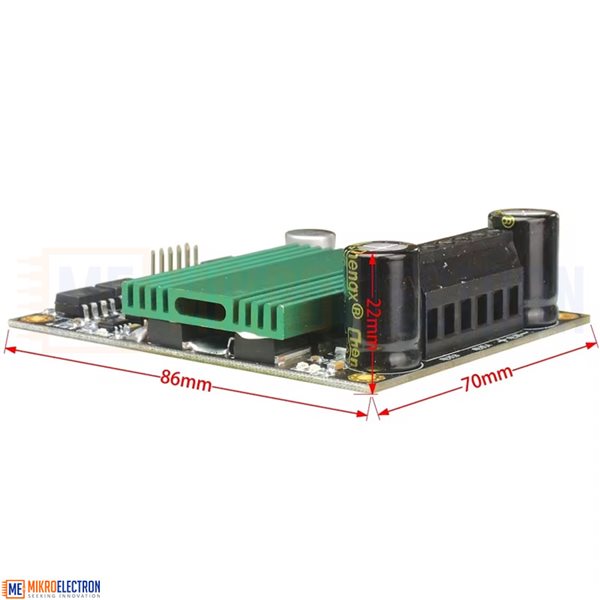

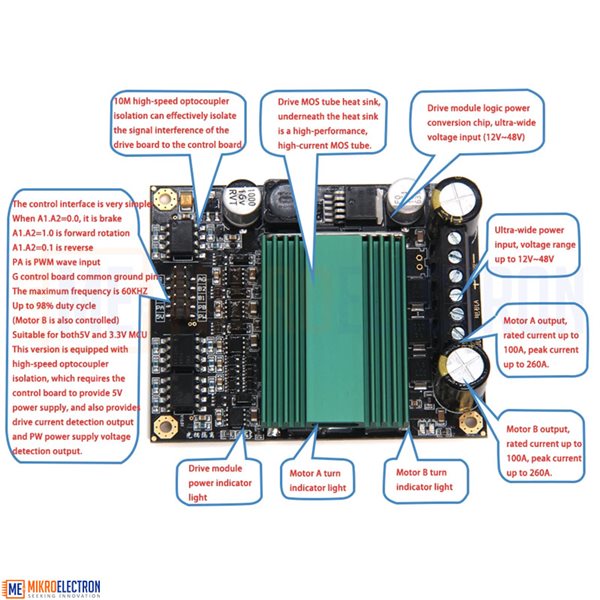

DC 12V-48V 100A High Power Dual Channel DC Motor Driver Module

Note:

this product can not connect RC Receiver( remote control)! The PWM signal requirement of our driver is that the frequency is above 10K, and the duty cycle is 0-98% (the PWM frequency of the general aeromodelling controller is below 1K)

Because different customers have different use conditions, we usually recommend that the 100A drive board use a single channel with power below 500W (continuous). If it exceeds 500W, the heat dissipation capacity of the drive plate may not keep up with that of the drive plate. Generally, the greater the current, the greater the heat on the main circuit, and the higher the temperature rise. At this time, the temperature exceeds the solder melting point on the drive plate, which is easy to burn.

On the other hand, the heating of the drive plate is related to the load and the frequency of the drive signal. The switch tube operates in the hard switching mode, and the higher the frequency, the easier the heating. At the same time, if the load is reactive (capacitive or inductive load), the higher the temperature (switch loss) will be. These are all need to be carefully considered when selecting the drive plate. It is better to leave enough margin, instead of selecting the 100A drive plate for the 100A load.

other note:

The reverse electromotive force of the inductive load. If the current is large, the load will impact the switch tube of the drive board. Although there is TVS tube protection, if the load of the TVS tube is exceeded, the TVS tube will also be broken down (failure) and finally the switch tube will be broken down (at this time, the drive board will be burned!) These are related to the current size and load If you mind, please do not buy.

Related Products

subscribe to our weekly newsletter