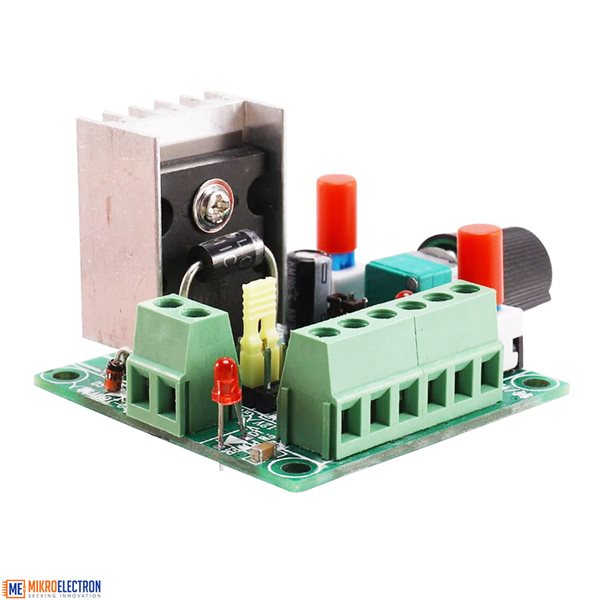

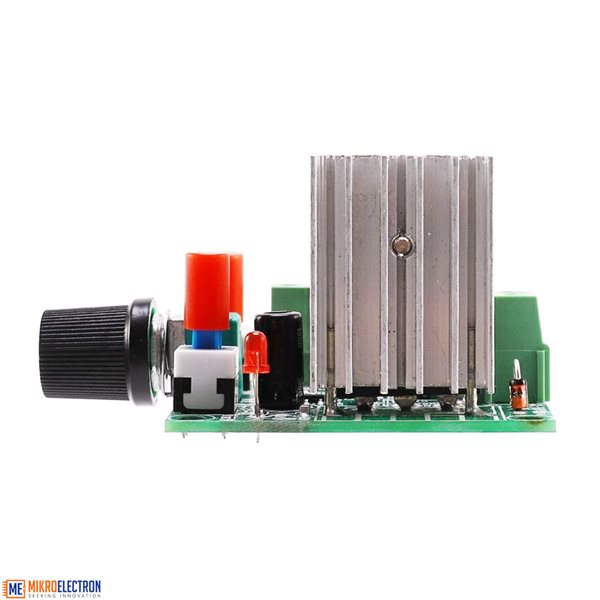

Stepper Motor Drive Simple Controller Speed Forwardand/Reverse Control PWM Generation Controller

Description:

Stepper Motor Drive Simple Controller Speed Forward and Reverse Control Pulse Generation PWM Generation Controller CNIM Hot

When the controller generates a pulse frequency signal, it can be used as a signal for the stepper driver. Drivers are also required to control the stepper motor.

This simple controller + Stepper motor driver + Stepper motor + DC power supply can form a simple control platform.

The controller can generate a pulse frequency signal, it can also be generated. PWM Signal pulse duration. There is a bouncing needle on the board., You can set options Select, the default setting should generate a pulse frequency signal.

REQ It generates a pulse frequency.

When the controller generates a frequency pulse signal, has a high, low frequency signal can be selected by a jumping needle, the frequency parameters are approximately:

High: 5.8 kHz-127 kHz

V: 590 Hz-15.8 kHz

Low: 82 Hz-2.3 kHz,

Frequency measurement: the number of available negative terminals (GND) two ports.

Power supply 2 Power input group, 2 groups A can only be connected to a group of power sources. the recommended power supply is 15 V. receive2 bit terminal power supply, neither positive nor negative, we must accept the opposite ..

One group is a power supply connected to DC.15-160VDC, the recommended working voltage15-80VDCAll right.

The other group is5-12VDC. when used in conjunction with the driver, it is recommended that minimum12V be used, do not use 5V power, 5V not too long, positive power supply "5-12 Venter", negative power supply "common cathode end".

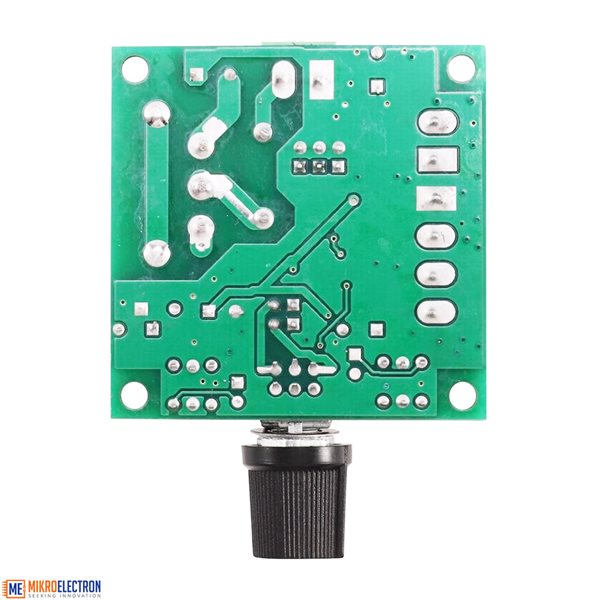

Connection instructions: Wiring each connection port, instructions for the silk sn next to the terminals. It can be connected to a step driver using a regular yin or common yang.

Color: green

Material: plastic

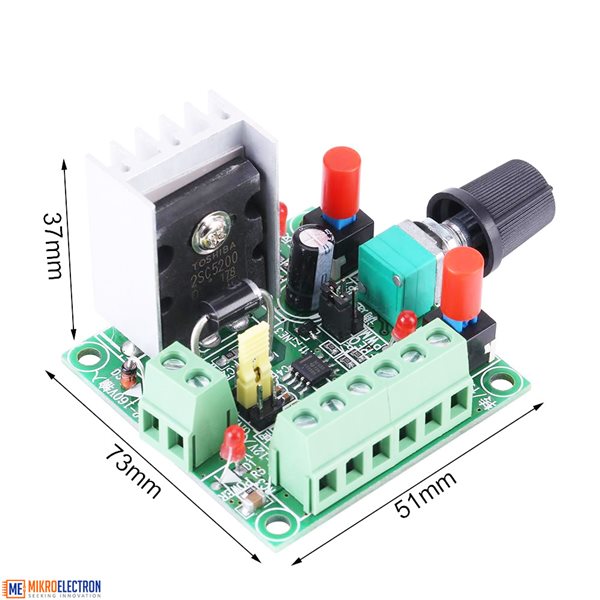

Size: 73*51*37MM

Package Contents:

1 x Stepper motor drive controller

Only the above package content, other products are not included.

Note: Light shooting and different displays may cause the color of the item in the picture a little different from the real thing. The measurement allowed error is +/- 1-3cm.

Kit include:

1 x Stepper Motor Drive

Related Products

subscribe to our weekly newsletter